Why AI Matters for Mid-Market Manufacturers Now

As manufacturing leaders, you're constantly balancing quality demands, operational efficiency, and cost pressures. While AI might seem like just another technology buzzword, it's actually solving real production problems for companies just like yours today.

The manufacturing sector faces unique challenges: increasingly customized products, shorter production runs, rising quality expectations, and ongoing labor constraints. These challenges align perfectly with AI's strengths in handling complexity, recognizing patterns, and making data-driven decisions.

Four AI Applications Ready for Implementation Today

1. Automated Visual Inspection: Beyond Human Limitations

Traditional quality control relies on human inspectors who, despite their expertise, face inevitable limitations from fatigue, inconsistency, and speed. AI-powered visual inspection systems can:

Continuously examine 100% of products with consistent standards

Detect subtle defects that human eyes might miss

Provide objective documentation for quality assurance

Free up skilled workers for more valuable problem-solving tasks

A mid-sized apparel printer implemented computer vision inspection and reduced customer returns by 38% while increasing production throughput by 22% - all without adding staff.

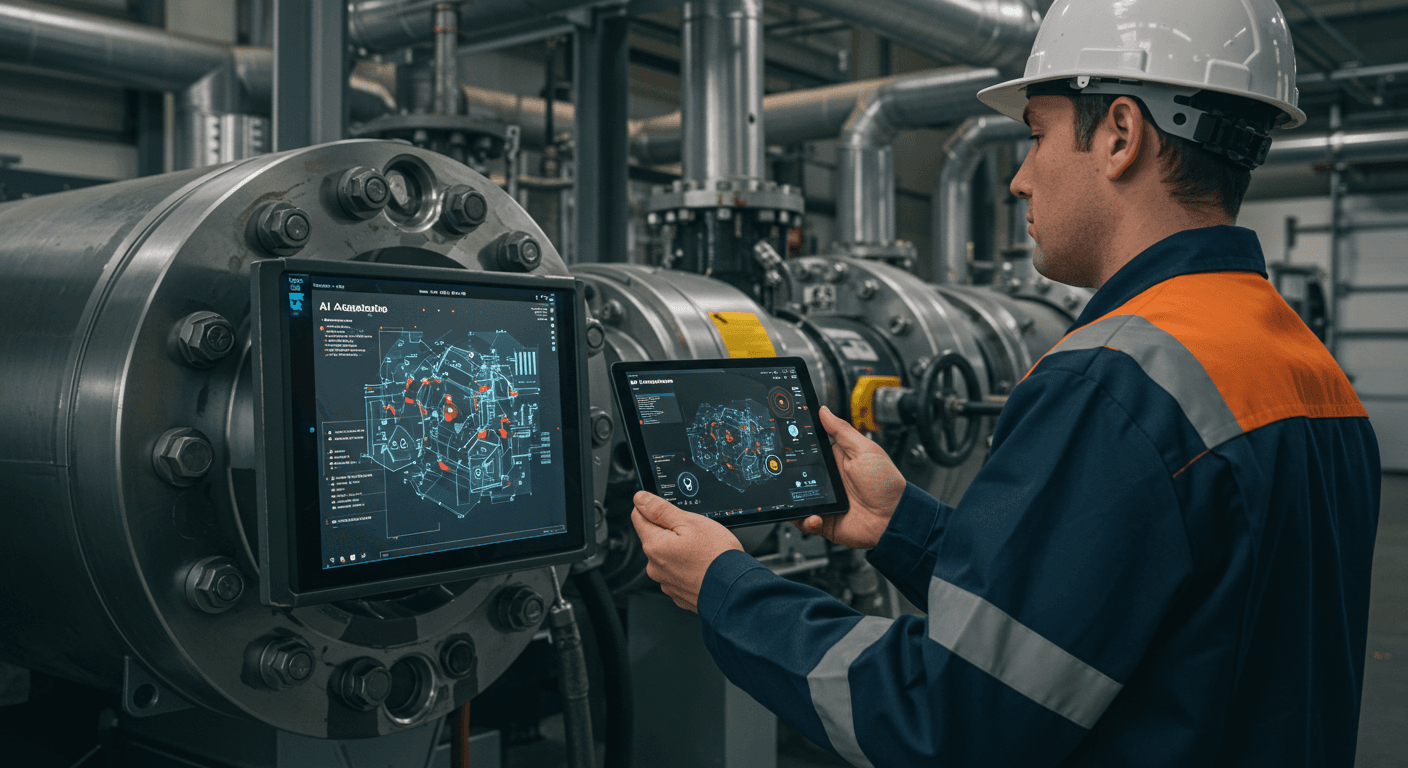

2. Predictive Maintenance: From Reactive to Proactive

Unplanned downtime remains one of manufacturing's most expensive problems. AI-based predictive maintenance:

Identifies patterns in equipment data that precede failures

Recommends maintenance before breakdowns occur

Optimizes component replacement timing to maximize useful life

Shifts maintenance activities to planned downtime periods

One commercial printer deployed sensors on critical equipment and used machine learning to predict failures. The result? A 52% reduction in unplanned downtime and 31% longer component life, with 78% of maintenance now occurring during already-scheduled downtime.

3. Production Scheduling Optimization: Beyond Human Calculation

Scheduling in today's variable manufacturing environment exceeds human cognitive capacity. AI scheduling systems:

Balance multiple competing priorities simultaneously

Adapt in real-time to disruptions and changes

Identify non-obvious efficiency opportunities

Optimize for business objectives beyond throughput

A packaging manufacturer implemented AI-driven scheduling and improved on-time delivery by 27% while reducing overall production time by 14%.

4. Order Processing Automation: Eliminating Information Bottlenecks

Manual order processing creates delays and errors while consuming valuable staff time. NLP-powered systems:

Extract specifications from customer emails and communications

Standardize terminology across diverse customer requests

Flag missing or ambiguous information for clarification

Automatically route orders to appropriate production paths

A custom packaging producer automated order processing with NLP and reduced processing time by 64% while decreasing specification errors by 43%.

Getting Started Without Breaking the Bank

Contrary to common perception, implementing AI doesn't require million-dollar budgets or data science teams. Here's a practical approach for mid-market manufacturers:

Begin With Clear Problems, Not Technology

Start by identifying specific operational pain points with measurable costs:

Which quality issues create the most rework?

Which equipment failures cause the longest downtime?

Where do information bottlenecks create delays?

The best AI projects solve defined problems rather than implementing technology for its own sake.

Focus on Data You Already Have

Most manufacturers already collect valuable data that remains underutilized:

Quality inspection records

Equipment maintenance histories

Production logs and ERP system data

Customer order specifications

Before investing in new sensors or systems, leverage these existing data sources.

Start Small and Scale Success

Begin with focused pilot projects that:

Demonstrate clear ROI within 3-6 months

Affect one production area or product line

Have well-defined success metrics

Build internal expertise and confidence

A successful pilot creates momentum and learning that can be expanded to other areas.

Consider Implementation Partners

You don't need to hire data scientists. Consider:

Industry-specific AI solution providers

Manufacturing-focused system integrators

Cloud-based AI services requiring minimal infrastructure

Look for partners with manufacturing experience who speak your language rather than technical jargon.

The Human Element: AI as Augmentation, Not Replacement

The most successful manufacturing AI implementations view technology as augmenting rather than replacing human expertise. Effective approaches:

Involve frontline staff in identifying problems AI could solve

Design systems that provide recommendations, not just commands

Create interfaces that explain AI decisions in manufacturing terms

Build continuous learning loops where human feedback improves AI performance

Staff who understand how AI supports their work become enthusiastic adopters rather than reluctant users.

Looking Forward: The Competitive Advantage of Early Adoption

Manufacturing has always rewarded operational excellence. Today's AI implementations create tomorrow's competitive advantages:

Consistently higher quality with lower inspection costs

More reliable equipment with optimized maintenance spending

Production flexibility without efficiency sacrifices

Faster response to customer needs without additional overhead

The experience gap between early adopters and laggards widens with each year, making "wait and see" an increasingly risky strategy.

Next Steps: Your AI Implementation Roadmap

- Identify 2-3 specific operational problems with clear business impact

- Audit existing data sources relevant to these problems

- Research industry-specific solutions addressing similar challenges

- Consider a 90-day pilot project focused on your highest-priority problem

- Design implementation with frontline staff involvement from day one

The mid-market manufacturers seeing the greatest AI success aren't necessarily the largest or most technically sophisticated - they're the ones who start with clear problems, focus on business outcomes, and build momentum through successful implementations.

What operational challenge could AI help your organization solve first?